What is Invisalign?

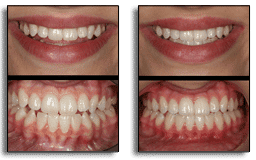

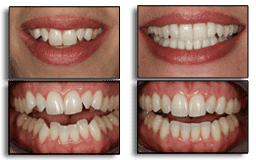

Invisalign is a series of clear plastic aligners that are virtually undetectable when used by the patient for teeth straightening. Here at the office of Dr. Lemongello in Palm Beach, Florida, we understand that the decision to straighten your teeth is a big step towards improving your appearance. That is why we are very excited by the possibilities that Invisalign can bring you. This modern-day solution to teeth straightening is sure to bring you the compounded benefits of straighter teeth, healthier gums, and easier cleanings with the help of your custom-made, removable, invisible aligners. Give our Palm Beach Gardens office a call at (561) 627-9000, and learn more about whether Invisalign is right for you!

What are the benefits of using Invisalign?

If you’ve wanted to get straighter teeth, but don’t want to have to deal with the hassle of conventional metal braces, Invisalign offers you the versatility and comfort of an appliance that addresses your needs, but does not interfere with your lifestyle. These clear aligners are almost unnoticeable when you wear them, and onlookers will not even be able to realize that you are wearing Invisalign. They are smooth and comfortable. Invisalign plastic aligners are also removable giving you the freedom to eat whatever you want during the treatment, unlike the many food restrictions that come with other teeth straightening methods. Also, because they are removable, these aligners are much easier to clean and maintain. Realistically, there are no other products out there that come close to the degree of comfort and convenience-that is the Invisalign promise.

How is Invisalign Different from Mail-Order Teeth Aligners?

How is Invisalign Different from Mail-Order Teeth Aligners?

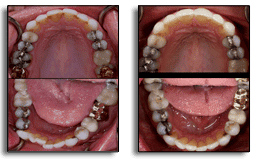

Invisalign is a proven, professional teeth-straightening system that has a few significant advantages over mail-order teeth aligners. When you get Invisalign, you receive a treatment plan designed by a dentist who has personally looked at your teeth, your mouth, and your x-rays. Mail-order services do not offer the extent of oversight. Invisalign aligners are custom made using sophisticated software that analyzes not only photographs of your teeth, but also digital dental impressions that accurately depict your dentition. Finally, when you get Invisalign, you receive periodic, in-person progress checks from the same dentist every time. Our goal in providing this treatment is to achieve the best outcome through personal care.

How do I know if Invisalign is Right for Me?

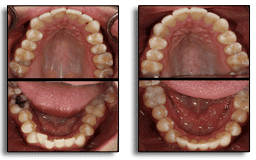

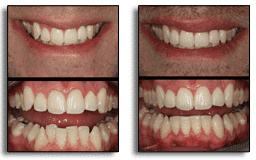

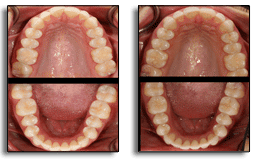

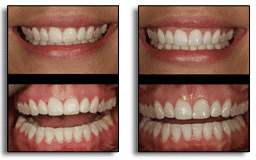

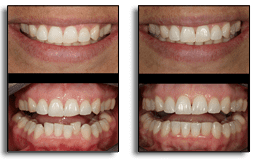

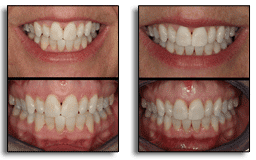

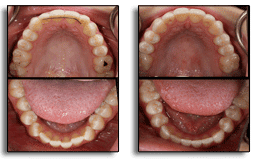

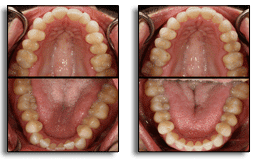

If you have mild to moderate misalignment, an overbite, crossbite, underbite, or other alignment concerns, you may be a great candidate for Invisalign. This system is commonly used to correct these minor bite problems, as well as turned teeth, overlapping, gaps, and more. The best way to understand what Invisalign can do for you is to schedule a consultation at our friendly, professional office!

What is the process of getting Invisalign?

What is the process of getting Invisalign?

-

- An initial consultation will help address any issues that the patient may have about the procedure. During this time, the dentist will perform a smile assessment to determine if you are a suitable candidate for Invisalign treatment.

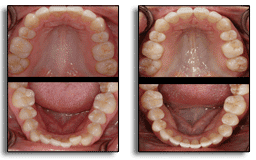

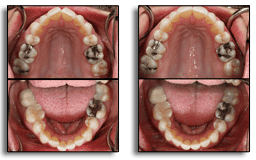

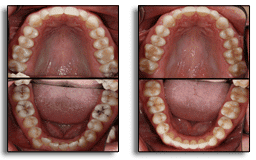

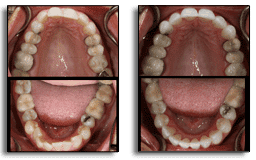

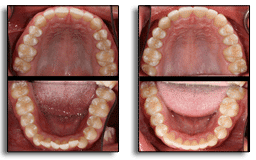

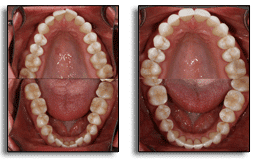

- The dentist takes x-ray images, photographs, and actual impressions of your teeth. These will be sent to the Align Technology Laboratory where a patented system will create three-dimensional images of your teeth. A corresponding treatment plan will be mapped out by the software based on calculated movements of the teeth throughout the prescribed treatment period.

- For each stage of the proposed treatment plan, a corresponding custom-made plastic aligner will be fabricated.

- The patient will be asked to wear the first plastic aligner for two weeks before switching out to the next set of aligners. This procedure will be repeated in two-week intervals until the teeth have been gradually moved into their correct position.

- Each case is individual and some cases take longer than others depending on the severity and complexity of your crooked teeth. Invisalign treatment typically takes about 12 months before the final outcome is achieved but minor tooth movements can be achieved in as little as six to nine months.

Because Invisalign aligners are removable, they may be conveniently taken out of the mouth for eating or for cleaning the appliance. For best results, however, Invisalign aligners are recommended to be worn at least 20 hours a day throughout the treatment period.

Invisalign makes it easy to straighten your teeth without bands, brackets, or wires. Forget everything you’ve heard about teeth straightening, because a proven technology now exists that let’s you straighten your teeth—invisibly. If you are looking for Invisalign invisible braces treatment in Palm Beach, then you have to come to the right place. Schedule an appointment with us today at our Palm Beach office.

When should I expect to see results after Invisalign?

When should I expect to see results after Invisalign?

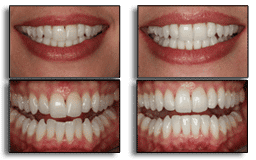

One of the advantages of Invisalign is that you can see your teeth throughout the entire process. Your smile looks natural from across the room. Only someone standing very close to you may notice your clear aligners. That said, you also will have an unobstructed view of your teeth. This means you will notice small changes beginning within the first few months of your treatment program, and more significant changes as you reach the end of your course of care.

How do I take care of my Invisalign Aligners?

How do I take care of my Invisalign Aligners?

It is important to take good care of your Invisalign aligners. It’s also easy to do so. We suggest the following:

- Always remove aligners before eating or drinking. The only exception is when you drink water, you may leave aligners in.

- Rinse aligners with cool or lukewarm water before inserting them. If you notice debris on an aligner, you can use a clean finger or cloth to carefully wipe it away.

- Rinse your mouth with water before inserting aligners, as well. This helps wash away debris from food and drinks that could increase your risk of cavities.

- Use a dedicated soft-bristled toothbrush once or twice a day to gently brush your aligners. Do not use the same toothbrush you brush your teeth with. Also, do not brush your aligners with toothpaste, just cool water.

- In addition to oral care, it is also important to have a carrying case for your aligners so you have a safe place to keep them when you are eating out.

Is Invisalign painful?

Is Invisalign painful?

Invisalign aligners are not painful. There are no sharp corners or edges, so there is minimal change in sensation to the tongue and cheeks. There is no part of an appliance that can get stuck on soft tissue, causing injury. Still, wearing Invisalign may be slightly uncomfortable. In order to have a straighter smile, it is necessary to move your teeth. Like braces, Invisalign achieves this by placing gentle but consistent force on the teeth that need repositioning. The first few days of wearing each new set of aligners may be slightly uncomfortable. The mouth may feel generally sore. Fortunately, this is a temporary sensation and one that can be managed with an over-the-counter pain reliever.

What if I’ve had braces or other types of dental work?

What if I’ve had braces or other types of dental work?

If you have previously worn braces and some of your teeth have shifted out of place, you may be a great candidate for Invisalign. Orthodontic relapse is relatively common because many people stop wearing their retainer too soon after completing their course of treatment. The good news about getting Invisalign after having worn braces is that your treatment program may not last very long. In these instances, we are often dealing with mild to moderate misalignment only, no serious bite issues.

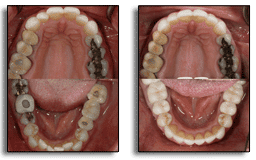

Invisalign clear aligners are custom made to fit over your teeth as they are at the time of treatment. If you have a dental crown or crowns, inlays or onlays, or fillings, your aligners will simply fit over them. Your teeth are moved at the root, beneath the gums and within the periodontal ligament. Therefore, the process should not be impaired by your dental restorations.

What People Say About Us!

“The many compliments we get are daily proof of the outstanding dental treatment we have received. Drs. Lerner and Lemongello’s experience and caring are evident every step of the way. We are delighted with the outcome and smile all of the time.” -Myra and David Ratliff

Click here to read more reviews.

Schedule an Invisalign Clear Aligners Consultation in Palm Beach Gardens!

Schedule an Invisalign Clear Aligners Consultation in Palm Beach Gardens!

To learn more about Invisalign Aligners or to determine whether you are a candidate for the appliances, be sure to schedule a personalized appointment with Dr. Lemer or Dr. Lemongello today! Call (561) 627-9000 today or fill out the form in our contact page, and our talented team will assist you with setting up your meeting. Our practice looks forward to serving you!